The construction sector is changing rapidly. Modern construction technologies are turning traditional jobsites into high-tech hubs where robots work alongside people and digital technologies manage every stage of a build. In work with private clients, I see growing interest in 3D-printed homes and smart building-management systems.

Innovation in construction no longer looks like science fiction — it’s today’s reality. The future of construction is being shaped here and now, like a giant LEGO set where each element fits precisely thanks to advanced building technologies.

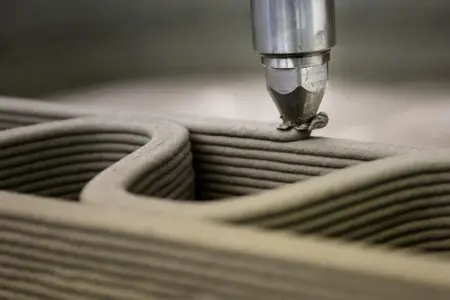

“The market for future construction technologies shows steady growth, with 3D printing in construction posting 29.3% annual growth,” — Grand View Research

BIM Technologies and the Digital Revolution in Design

BIM has turned construction from a chaotic process into a symphony of precision. Building information modeling creates a digital twin long before the first shovel hits the ground — like a strategy game where every move is calculated in advance.

In a recent residential project, the BIM model revealed 187 clashes between engineering systems. Imagine discovering those during installation! Modular construction paired with BIM cuts schedules by about a third. Automation of construction processes is becoming a necessity, not a luxury.

The key benefits of BIM span the entire project lifecycle:

- Up to 80% fewer design errors.

- Approvals accelerated 3–4×.

- Material savings up to 20%.

- Cost-estimate accuracy up to 95%.

- Virtual walkthroughs before construction begins.

This transformation turns construction from an art into an exact science with predictable outcomes.

Robotics and Smart Tech: A New Level of Building

Construction robotics is rewriting the rules. Bricklaying robots place around 1,000 bricks per hour — a blistering pace! Smart-building technologies turn ordinary structures into self-learning organisms that adapt to occupants’ needs.

Notably, AI makes construction highly efficient through big-data analysis and forecasting. In practice, crews are skeptical of robots at first, then can’t imagine working without them. Energy-efficient buildings can consume up to 70% less energy than conventional ones.

“Self-healing materials can ‘repair’ micro-cracks on their own, doubling or tripling a building’s service life,” — Institute of Building Technologies report

By the way, 3D printing can erect a house in 24 hours. Cost? From about $15,000 for a small cottage. Eco-friendly materials made from recycled plastics and biocomposites are becoming the basis of printed structures.

Modern robotics spans the process end-to-end:

- Autonomous excavators with centimeter-level GPS accuracy

- Drones for quality control and safety monitoring

- Welding robots for steel structures

- Automated material-feeding systems

- AI algorithms for logistics optimization

Integrating these innovations creates production lines where humans orchestrate and robots handle the routine.

Moreover, a construction digital twin can forecast building behavior 50 years ahead. Imagine seeing how your home will look half a century from now!

Tomorrow’s construction technologies already operate on real projects worldwide. Firms embracing advanced tech today will lead the market tomorrow. The industry is racing toward full automation and sustainability — inevitably.